Explore the role of passive fire protection solutions and materials in hospitality infrastructures – and how recent relighting renovations are prompting hotel developers to reassess and specify the appropriate level of life safety measures.

Introduction

Often, looked at as “a home away from home”, hospitality buildings – such as hotels – serve as welcoming spaces that offer comfort, convenience, and an opportunity to explore new communities, both near and far.

Whether located in a bustling city or quiet countryside, hotels serve as gateways for tourism, business, and family engagement. In addition to serving as a gateway for connections, these buildings often act as a gathering place for a large volume of people, such as weddings, conferences, and community events.

Providing to be a strong asset to our community and others, it is critical that these infrastructures are constructed with the upmost level of life safety. Over the past several years, architects and developers have been adopting stringent building codes to their new-construction architectural design details – ensuring lives and property remain safe.

Understanding the Growing Threat of Relighting Renovations

In recent efforts to move towards a “greener” future, many existing hotels have begun incorporating energy-conserving practices. From encouraging guests to reuse towels to utilizing keycards as a device to regulate lighting and climate control – hospitality buildings have fully embraced the ideas of energy conservation and sustainability.

To build onto their current strategies of sustainability and energy conservation, hotel developers have discovered a way to greatly improve their building’s energy efficiency levels – replacing current recessed can lights with LED wafer-styled downlights.

Known to consume less electricity and longer lifespan, low-profile LED wafer-style downlights are an ideal choice to decrease energy levels – which translates into lower utility bills as well.

Unfortunately, this highly-beneficial renovation comes at a cost – the safety of the building and its current occupants.

Addressing Compromised Fire-Resistance Rated Ceiling/Floor Assemblies

When contractors extract existing recessed lighting fixtures during renovations, the resulting ceiling openings are often left exposed and unprotected. Thinking this can be resolved by installing the new low-profile LED wafer? The answer is no.

In hospitality infrastructures, such as hotels and inns, ceiling and floor assemblies are often required to meet a fire-resistance rating. These assemblies are designed to prevent the vertical spread of fire, allowing an extended evacuation and response window.

Prior to any penetration, these assemblies serve as a barrier against the rapid transmission of flames, smoke, and heat between floors. However, once compromised by the installation of a fixture, the assembly’s integrity is compromised. If not properly sealed or protected, these openings will become the prime pathways for fire to accelerate throughout the building, both vertically and horizontally.

Why does the installation of a standard low-profile LED wafer fail to adequately address the issue?

When exposed to extreme heat, the fixture itself may melt, leaving the opening fully exposed. In such cases, the unprotected penetration acts as a conduit – enabling fire to spread from room to room and floor to floor within minutes. This not only undermines a building’s level of fire protection but also poses a serious threat to life safety and property.

How are architects and developers addressing this fire safety issue?

Adopting strict building codes, such as the 2015 IBC Section 714.4.2, architects and developers have begun integrating both the LED wafers and a fire-rated solution. With this integration, the integrity of the fire-resistance rated ceiling/floor assembly is reinstated.

Note:

For new construction,

Please refer to your local building code to establish if your hotel’s design details require fire-resistance rated ceiling and floor assemblies.

For relighting renovations,

Examine the original design specifications to determine whether the building’s ceiling and floor assemblies are constructed to maintain a fire-resistance rating.

Passive Fire Protection in Relighting Renovations

When deciding on the specifications of fire-rated solutions in your relighting renovations, there are several questions developers and contractors need to ask themselves.

- Has the fire-rated solution undergone proper testing at an accredited third-party testing laboratory?

- Can I effortlessly integrate the fire-rated solution into my current design?

- Does the solution require a large volume of labor?

Regardless of whether you are planning to use a fire-rated light or fire-rated drywall box, it is critical that you can accurately answer all the questions above.

Tenmat in Relighting Renovations

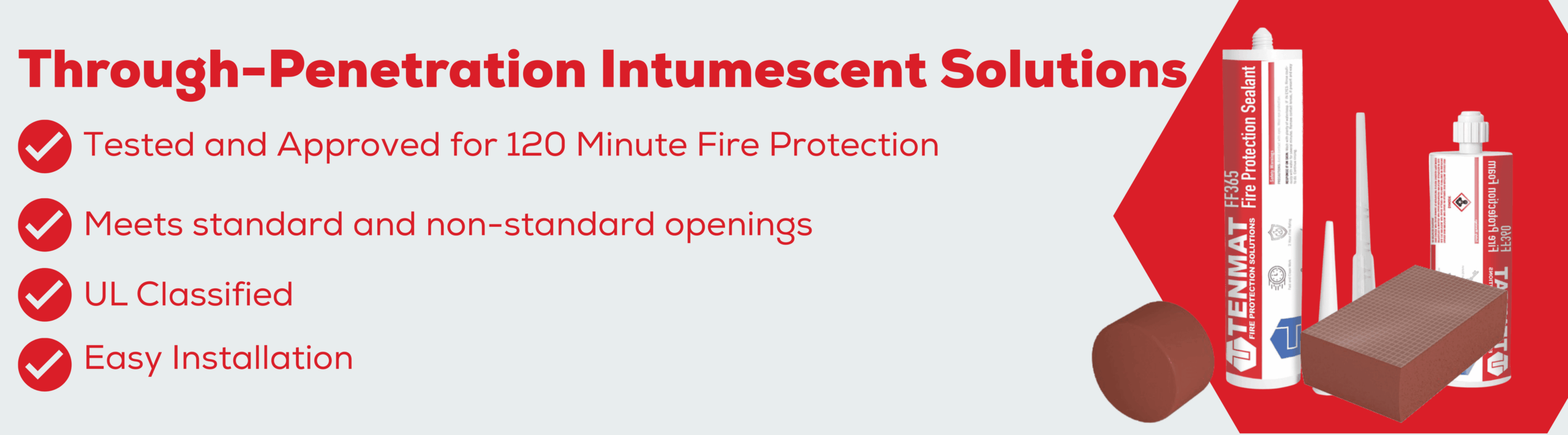

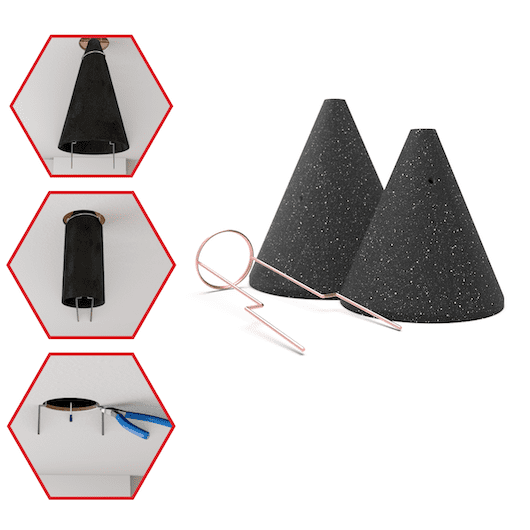

Designed with a flexible, lightweight intumescent technology, Tenmat’s FF109-200 and FF109-250 allows hotel developers and contractors to reinstate their fire-rated ceiling/floor assemblies while meeting their recently adopted sustainable practices.

Additionally, both the FF109-200 and FF109-250 Fire-Rated Covers have:

- Undergone proper testing and approval from Intertek (ETL),

- Retrofitting Capabilities, allowing contractors to easily install the solution in pre-existing ceilings, and

- A Flexible, Light Composition and require no additional tools during the installation process.

Explore Our Version of Fire-Rated Lights Here.

Next Steps for Hotel Groups and Developers

As the hospitality industry continues to evolve through sustainability-driven renovations and energy-efficient upgrades, the importance of maintaining proper passive fire protection measures cannot be overstated. While relighting renovations—such as the integration of low-profile LED wafer lights—offer clear benefits in terms of energy savings and operational efficiency, they also introduce critical challenges to the integrity of fire-resistance rated ceiling and floor assemblies.

Architects and developers must remain vigilant in ensuring that any modifications to existing infrastructure do not compromise life safety. The installation of recessed fixtures without proper fire-rated protection can create vulnerabilities that accelerate the spread of fire, smoke, and heat—placing occupants and property at significant risk.

By adhering to established building codes and integrating tested fire-rated solutions, such as Tenmat’s FF109-200 and FF109-250 covers, professionals can confidently balance energy efficiency with fire safety.

Ultimately, passive fire protection is not a secondary consideration—it is a foundational element of responsible design and development in hospitality environments. As buildings become smarter and greener, their safety systems must evolve in parallel, ensuring that comfort and innovation never come at the expense of occupant protection.

Treating the Tumor of Through-Penetration Openings.

Treating the Tumor of Through-Penetration Openings.