Advanced Passive Fire Protection Materials & Solutions for Modular Construction

Building Blocks for the Safety of Our Future Communities

The Future Built Off-Site.

Over the past several years, there has been a sharp increase in demand for more effective and efficient building processes within the construction industry. This heightened demand primarily stems from the limitations associated with traditional construction practices, including issues related to safety, construction quality, and project timelines. The answer to this problem is modular or off-site construction. Offsite construction, also commonly referred to as modular construction, is a construction practice during which the primary components are assembled under controlled conditions within a factory, before being transported on-site for final assembly.

Life Safety in Modular Construction Applications.

Modular, or off-site, construction practices have an assortment of benefits, compared to traditional construction practices; however, the demand for passive fire protection is equivalent to the demands in traditional construction practices. By building in passive fire protection at the point of manufacture, off-site structures offer builders a vast range of benefits making final construction an easier task. At Tenmat, we have worked with industry leaders in modular construction to formulate a range of firestopping solutions and materials that exceed the industry’s standards for passive fire protection and the demands of the modular industry.

Developed for Every Application.

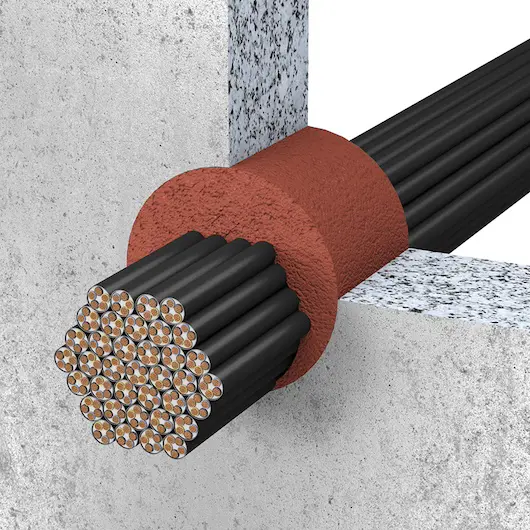

From edge protection to through penetration, Tenmat offers “no build” UL fire-tested solutions, which have the ability to be installed in a matter of seconds and the flexibility to cater to the most difficult openings with no additional assembly or tools. Not to mention, all of Tenmat’s firestopping solutions have the ability to be implemented into the off-site structures, allowing for time and labor savings. Tenmat FIREFLY 104E is a dark grey intumescent paper which generates high expansion pressure when exposed to fire or heat. It is suitable for applications such as door and glazing seals, door hardware, ironmongery protection, damper seals, gap sealing or a variety of gasketing applications. Its high flexibility allows it to be wrapped or folded to suit various applications but produces an excellent structure helping to maintain integrity throughout the fire. In comparison, Tenmat’s Firefly FF107 is an exceptionally powerful intumescent which combines fast reaction with high expansion and pressure generation. This material allows for an additional thickness for construction joint and gap sealing applications where the high expansion characteristics lead to economical material usage.

Composed with Intumescent Material and Flexibility.

The FF160 Fire Protection Plug, made of a rapidly expanding intumescent foam, is the ideal solution for through-penetration firestop systems. Its flexible and lightweight materials allow for decreased project lead times and permit accessibility to penetrate additional wires through this fire-tested and approved solution. If you are seeking to fire rate smaller wall penetrations, Tenmat offers a fire protection foam, the FF360. This sealant is recommended for blank openings, metal pipes, conduits, wires, and mixed penetrations in solid floors and ceilings. Its high expansion and insulating properties of the material ensure that both flame spread and smoke, are stopped for 120 minutes.

Meeting the Building Code.

Compared to traditional construction codes, modular builders are obligated to ensure their projects comply with the latest local building codes, usually aligned with the most recent version of the International Building Code (IBC). Consequently, in modular construction applications requiring fire-resistance rated ceiling/floor assemblies, there is a mandatory requirement to reinforce the integrity of a fire-rated ceiling after the penetration of a ceiling fixture. Whether you penetrate the ceiling with a recessed can light, LED downlight, troffer luminaire, or in-ceiling loudspeaker, Tenmat has a solution to meet those building code requirements.

Tenmat Meets Modern Construction Practices.

In the instances that the off-site application requires a nonstandard opening, Tenmat has the manufacturing capabilities to design 2D or 3D custom solutions, in various sizes, shapes, and thicknesses. At Tenmat, we have an on-site research and development team, who will work exclusively to achieve the precise solution for your particular application.

Please reach out to one of Tenmat’s team members at

+1-800-821-3436

for further assistance.

Tenmat’s modular firestopping materials and solutions offer:

Improved efficiency

Shorter Construction Times

Design and Manufacturing Benefits