Explore how Tenmat’s Advanced Intumescent Solutions and Materials have shaped the future of passive fire protection in modern-day construction.

As of 2024, the United States is home to 19,479 cities, towns, and villages – each containing an even greater number of communities. Now, each community can contain a multitude of different structures. Some contain bustling shopping malls, others are developing new multi-family complexes, certain ones include a wide range of various healthcare centers, and a number of them hold all the above and more.

Not one community is the exact same. But every community wants to protect the people and property within theirs. Therefore, whenever a community is getting a “face lift” or expanding internally or externally, life safety is the No.1 priority of the growing community.

To uphold this priority, communities need to prepare its redeveloping or new-construction buildings to withstand all potential disasters – especially the unexcepted ones.

The Beginning of Passive Fire Protection

Fire outbreaks have always been known to negatively impacted communities, especially when it comes to protecting properties and the lives within them. Over hundreds of years, countless safety measures have been put into place to fight off the potential damage of fires. From fire extinguishers to automated sprinkler systems, building code officials, construction professionals, and community members believed that they all their bases were covered.

However, this assumption was incorrect. Before 2006, unprotected openings were an unrecognized life safety hazard in many communities. These openings included openings created from recessed lights, in-ceiling loudspeakers, wires, cables, etc. Without being properly reinforced, these openings acted as a catalyst for the fire. Without these openings being improperly fire-rated, heat, smoke, and flames can spread rapidly throughout the building – endangering the integrity of the building and the lives of its occupants.

As a result of this discovery, the 2006 International Building Code adopted several building codes which required construction professionals to reinstate the fire-resistance rating of a wall, ceiling, or floor assembly. This is where we introduce the concept of passive fire protection.

Passive Fire Protection is the system which slows or prevents the spread of fire within a building – utilizing fire-rated materials and solutions to achieve this. This system works by using fire-rated solutions, such as intumescent recessed light covers, to contain fire, heat, and smoke, by limiting heat and fire spread to a single compartment within the building.

Causing fires to become smaller and contained, passive fire protection (PFP) systems have the ability to increase the response time for first responders and provide additional evacuation time for the building’s occupants.

Tenmat’s POV: The Importance of Passive Fire Protection

Following the building code adoptions, construction professionals were seeking PFP solutions and materials that can resolve the unprotected openings within their design details. However, construction professionals struggled to find a fire-rated solution, which has been

- Properly tested and certified by an accredited third-party testing laboratory,

- Fitted to meet the design requirements of the application, and

- Engineered to be easily installed into a wide range of building types.

Dedicated to protecting the safety of present and future communities, Tenmat developed an adaptable form of passive fire protection technology, intumescents. With the release of this technology, construction professionals were now able to meet local building codes while simultaneously fulfilling their design concepts.

Through our manufacturing capability to produce intumescents, which offer various expansion rates and char production, Tenmat’s Advanced Intumescents can protect a wide range of unprotected openings.

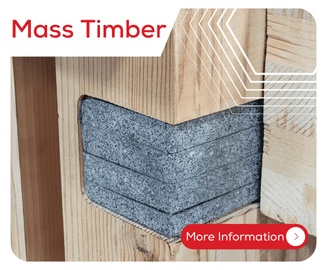

With this versatility, our intumescents can be specified into a diverse range of unprotected openings. From ventilated air cavities in a rainscreen assembly to recessed fixtures in a fire-rated ceiling assembly, Tenmat’s Advanced Intumescent Materials and Solutions can reinforce the integrity of these fire-resistance rated assemblies.

Intumescents in Passive Fire Protection

As previously mentioned, our Intumescent Solutions and Materials can meet the design requirements + passive fire protection standards of a wide range of building types. To discover our capabilities for each popular building type, please explore our quick overview.

Enforcing Life Safety + Passive Fire Protection

Even though, Tenmat’s Solutions and Materials evolved alongside modern construction – the visibility of passive fire protection in modern construction remains on the lower side. Admittedly, this lack of visibility remains valid, due to the extensive, ongoing list of safety measures code officials and construction professionals are required to memorize and specify.

On top of curating our wide range of Advanced Intumescent Solutions and Materials, Tenmat is dedicated to educating local building code officials and construction professionals about unprotected openings in numerous building types. To encourage these individuals to gain more knowledge about these life safety hazards, we offer free 1-1 educational webinars for anyone who may be interested.

Schedule Your Free Educational Webinar Here.

AIA Course: Intumescent Fire Block for Ventilated Rainscreen Systems

Safety Hazards for Unprotected Ceiling Openings

Final Remarks

As communities across the United States continue to grow and evolve, so too must the strategies used to protect them. Passive fire protection can no longer be a secondary consideration – it is one of key components in the foundation of our future infrastructures.

Here at Tenmat, our Advanced Intumescent Solutions and Materials have not only addressed a once-overlooked life safety hazard but have also redefined how unprotected openings are managed in fire-rated assemblies.

By combining innovation, rigorous testing, and practical design adaptability, Tenmat encourages architects, builders, and building code officials to meet today’s safety standards without compromising on design or functionality.

As we look forward to the future, Tenmat remains committed to advancing passive fire protection technologies and educating industry professionals about relevant building code adoptions – ensuring that every structure, in every community, is built with safety from its core.